Plate Type Fresh Water Generator:

If the condenser and evaporator Heatexchangers of a fresh water generator is composed of plates then that type of freshwater generator is called as a Plate type freshwater generator.

Principle of plate type FWG:

Main Engine jacket water passes through the evaporator at 80 degree. Feed sea water enters the evaporator through the orifice at the feed inlet. Due to low pressure in the chamber, sea water boils and get converted to steam. The carry over water droplet and water spray is removed by Demister.

The separated water droplets gets collected as brain which is extracted by brain ejector. The steam then enters into the condenser, where it gets cooled down to form fresh water.

Distillate pump help to pump out this fresh water from the condenser.

The separated water droplets gets collected as brain which is extracted by brain ejector. The steam then enters into the condenser, where it gets cooled down to form fresh water.

Distillate pump help to pump out this fresh water from the condenser.

Main components of plate type FWG are

- Two Heatexchangers which are condenser and evaporator

- air braine jectors

- sea water pump and Distillate pump

- salinometer

- Demister

- Water flow meter etc.

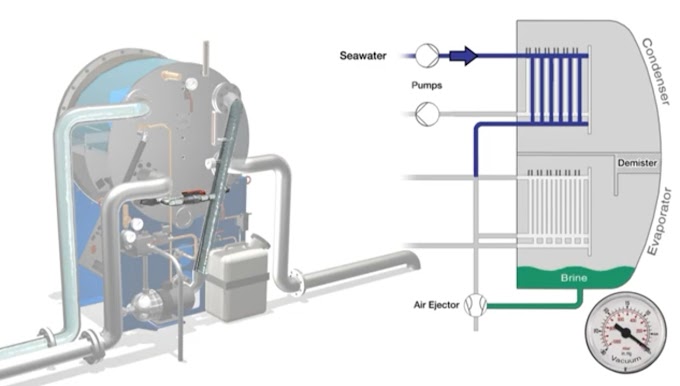

Now You can see all these things in the

line diagram:

Now ,we are going to look out these things in detail…

Heat Exchangers:

This is the essential part and also the huge in size.

Both the Heat Exchangers( Condenser and evaporators )are made of corrugated titanium plates.

The plates are corrugated with horizontal or chevron pattern corrugations which will help to increase the heat exchange surface .this is ,tends to increse the efficiency of heat exchanging.

The plates are corrugated with horizontal or chevron pattern corrugations which will help to increase the heat exchange surface .this is ,tends to increse the efficiency of heat exchanging.

Demister:

Demister helps to remove the carry over of sea water droplets and water spray.

It is made of layered knitted wire of monel metal.

The removing of carry over of salts which are accumullated at bottom of chamber.

without demister ,it is very difficult to make the fresh water easily.

It is made of layered knitted wire of monel metal.

The removing of carry over of salts which are accumullated at bottom of chamber.

without demister ,it is very difficult to make the fresh water easily.

Brain Air Ejectors:

This is also an crucial part and also the very small in size.

It is used to remove air and brain from the chamber which is The removing of carry over of salts in the vapour which are finally accumullated at bottom of chamber and which is mailnly helps in creating the vacuum and maintaining it for while,.the creating of vaccum inside the chamber is done the boiling of water rapidly.

It is used to remove air and brain from the chamber which is The removing of carry over of salts in the vapour which are finally accumullated at bottom of chamber and which is mailnly helps in creating the vacuum and maintaining it for while,.the creating of vaccum inside the chamber is done the boiling of water rapidly.

Sea water and distillate pump:

both of this are the nesscesary things to achieve the pumping of water,we can not pump out anything without the pump,so the purpose of pump unaviodable in this system.

Both the pumps are kind of centrifugal pump.

Distillate pump helps to pump out the freshwater from condenser to fresh water tank.,and seawater pump supply sea water to condenser and as well the evaporator.

Salinometer:

This is the type of electronic device which used to Check the salinity of the water.

The salinometer controlls Three way valve ,as shown in fig. If the salinity is high, water send back to the evaporator inlet.(Salinity usually max 10ppm),.

If the salinity is not high the water send to fresh water tank through the distillate pump.

Fresh Water Generator Working Principle:

Only distinction in rather than plates, condenser and evaporators ar tubes. A typical line diagram of tube kind fresh generator is given below.

Basic principle of all low fresh generator is that, boiling purpose of water may be reduced by reducing the pressure of the atmosphere close it. By maintaining a coffee pressure, water may be cooked at low temperatures say fifty degree Centigrade.

The supply of warmth for the water generator may well be waste heat rejected by main engine jacket cooling water.

The Plate type water generator explained below uses the warmth from main engine jacket cooling water to provide drinkable water by evaporating brine because of the high vacuum, that allows the feed water to evaporate at a comparative temperature. Steam may also be used as a heat supply rather than main engine jacket cooling water.

This type of water generator is predicated on 2 sets of shell and tube heat exchangers, one acting as evaporator or heater and alternative as condenser.

The combined air/brine ejector creates evaporator chamber vacuum condition by driving ocean water pass through air/brine ejector, and ocean water equipped by the ejector pump to be delivered to ejector for putting off the brine (concentrated seawater) and air.

While coming into to the evaporator chamber temperature of feed water are going to be around fifty degree Centigrade.

Feed facility rate to the evaporator is fastened by associate degree passage fitted at the feed recess. thanks to the vacuum condition within evaporator feed water evaporates at this temperature.

The water spray and droplets ar part far from the vapour by the device mounted on prime of the evaporator and part by a incorporate warmer.

The separated water droplets fall into the brine, that is extracted by the water ejector.

The desalted vapour, that passes through the warmer, can are available in contact with the condenser, wherever it'll be condensed by means that of incoming cold brine.

The H2O is then taken out by integral fresh pump (distillate pump) and controlled by hydrometer and magnet valve.

If the salt content of made water is high, magnet valve diverts the fresh to the shell facet of fresh generator, associate degreed problems an alarm signal.

so as to induce higher suction head, liquid pump is placed at the bottom attainable location within the water generator plant.

this is often as a result of the water generator shell is at a lower pressure.

liquid pump get most net positive suction head with the peak of liquid column within the suction line.

Thermometers ar put in for management of brine to the condenser and jacket cooling water to the evaporator. These thermometers allow management of each heating and cooling of those units. The hydrometer or salinity indicator is connected to remote alarm so terribly high salinity is straight away registered at the engine room of the ship.

Procedure :

Generators is equipped with medical aid units (Chlorination, UV-radiation and Silver ionization), pH-adjustment and rehardening filters.

- The water pump is enabled through an effect panel.

- when passing the condenser section the water can flow through the air-brine ejector.

- A small a part of the water flow is employed as feed water to the evaporation section, wherever it's then divided into every second channels.

- Through a suction method the air-brine ejector removes the air from within the casing and also the excesive feed water.

- when most of five minutes a vacuum of approx ninetieth is reached.

- Open the valves on the new water water and outlet piping line.

- The evaporation of the feed water can begin straightaway.

- The vapour can flow through the warmer and can be condensed within the condenser section.

- Please begin the fresh pump when a most of two minutes when gap for the new water line.

0 Comments